Strategic importance of the pilot

Aligned with the EU’s 2022 framework, which prioritizes battery reuse and high recycling efficiency. It introduces an innovative "battery recycling" model centered on fine disassembly for maximum reuse of cells, modules, parts, and residual energy. By using standardized, advanced methods, the project supports EU goals for increased material recovery and reduced GHG emissions in the recycling industry, ensuring compliance with new regulations and contributing to a cleaner energy transition.

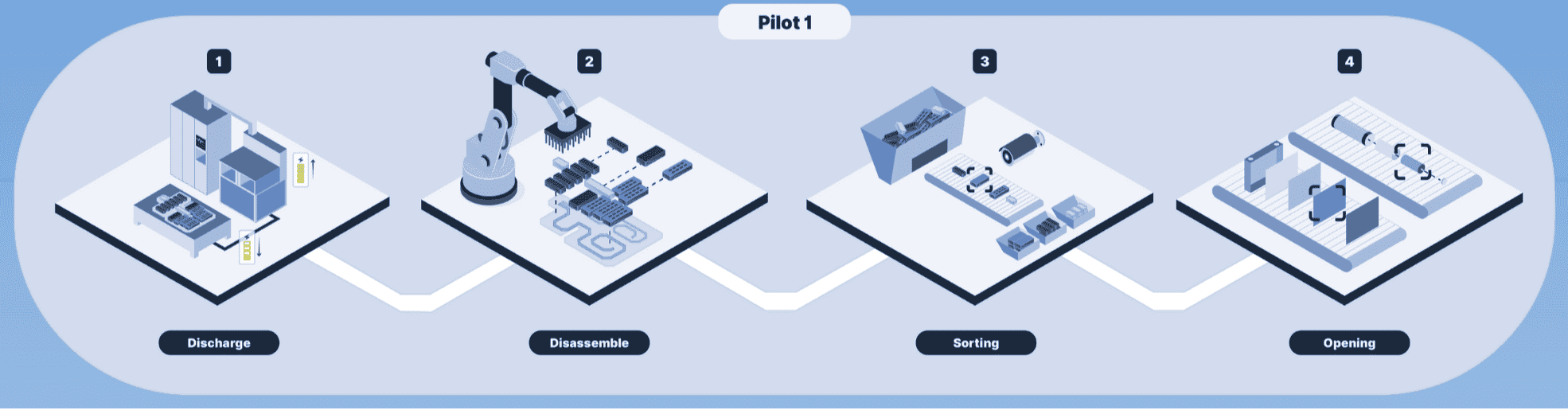

Target process-chain

Wide set of available manufacturing technologies (discharging, vision based de-soldering of packs, sorting, cell cutting, sorting of raw material, shredding and separation, safe stocking and transportation) will be complemented by a rich set of AI based techniques supporting in detail: cell degradation prediction, feature recognition and interpretation, process chain setup, human exposure to health and safety risks, data tracking and protection.

Target KPIs

- Variable part mix (average of 60 battery models) for e-bikes and EVs.

- The average assembling/testing for a battery made of 6000 cells is 300 hours.

- The average dismantling time for the same battery configuration is 450 hours.