Pilots

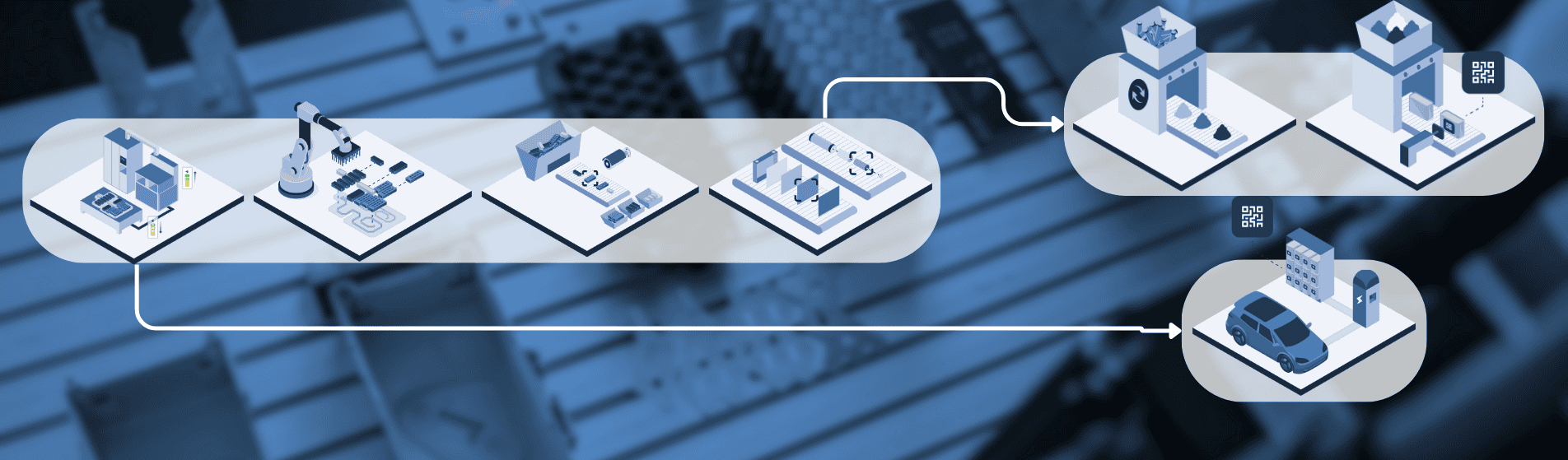

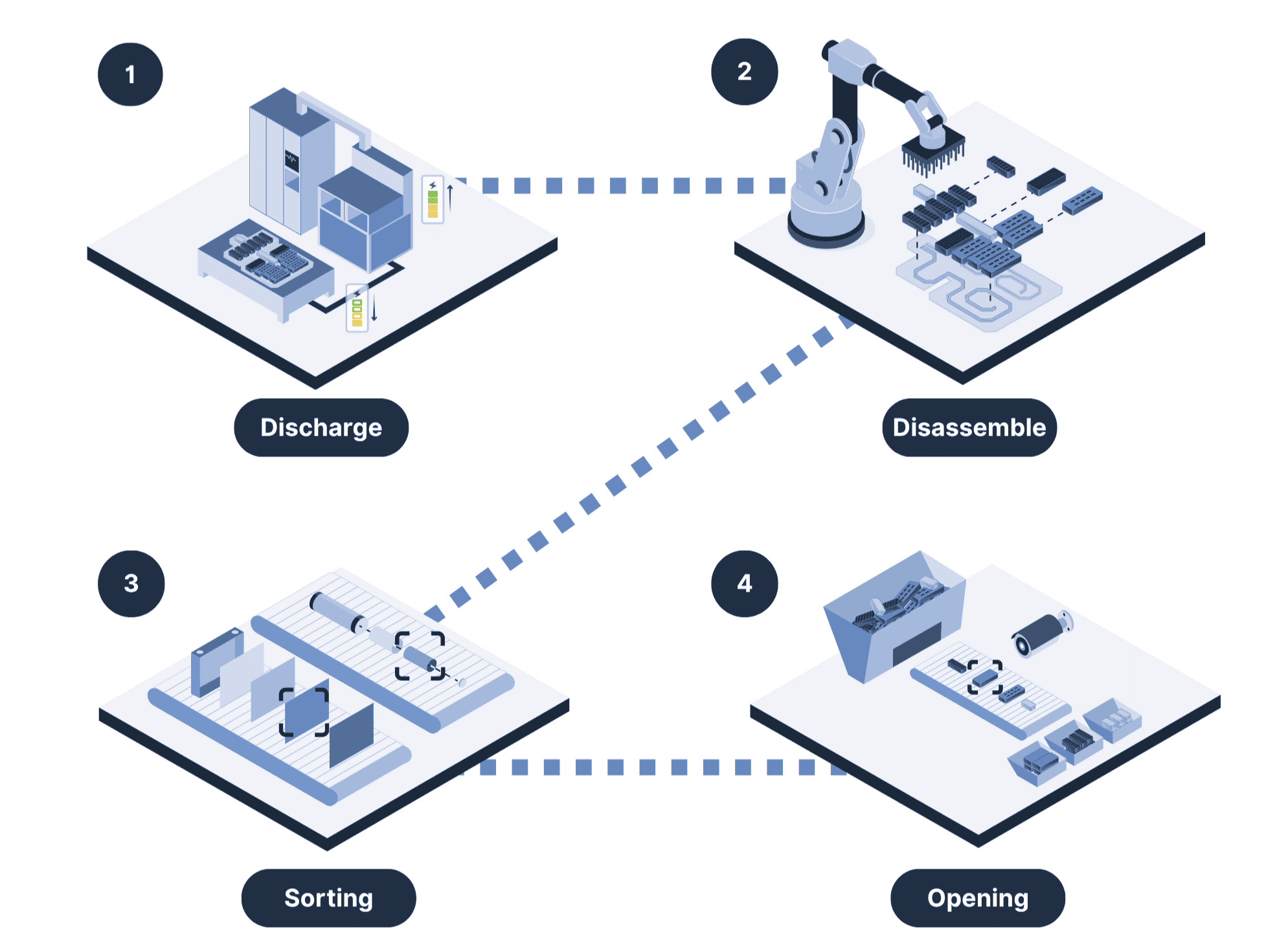

PILOT 1 - D2C Discharge, Dismantling and Sorting

Our battery dismantling pipeline safely processes used packs for reuse and recycling. Stages include smart discharge, vision-guided disassembly, and automated sorting. Integrated sensors monitor safety, while supercapacitors capture energy. The process maximizes recovery, efficiency, and sustainability.

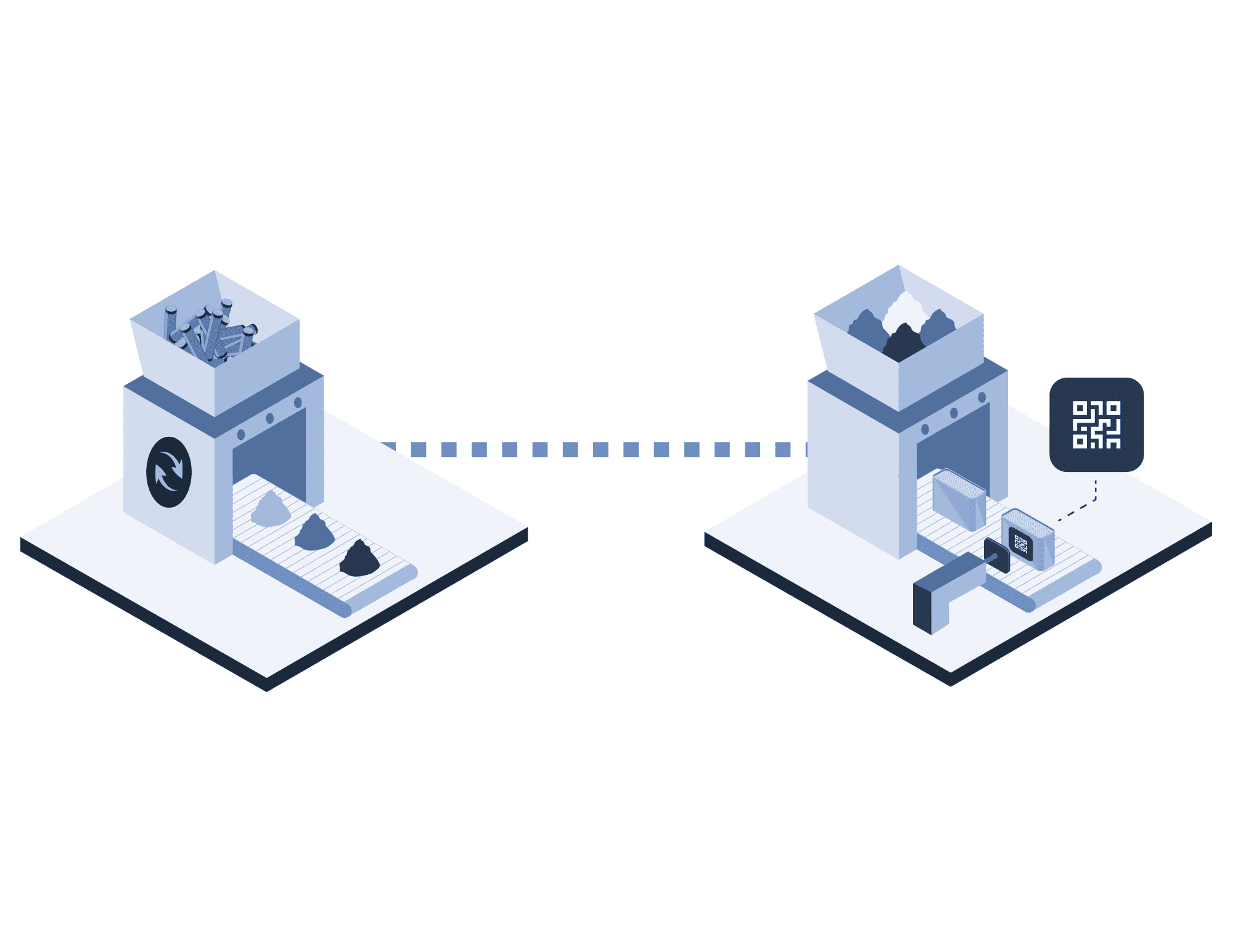

PILOT 2 - Material Recycling Assessment

The pilot validation processes to recycle and refine materials from battery dismantling. Key focuses include extracting metal-based precursors (Li, Co, Ni, Fe), recovering graphite and other carbon materials, and recycling electrolytes and polymers. Continuous analysis will guide efforts to enhance reusability in battery applications.

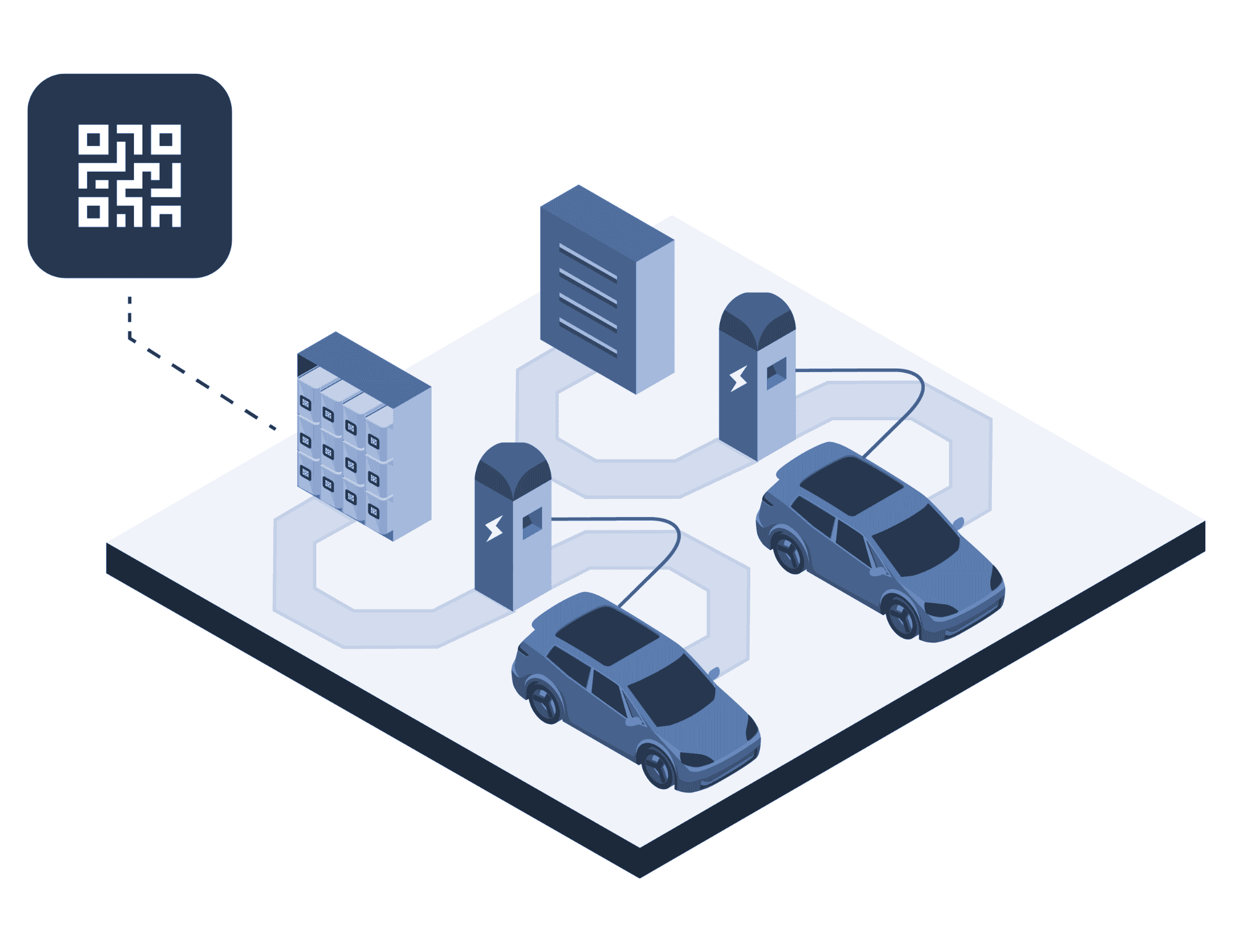

PILOT 3 - Second-Life Module and Pack Assessment

This pilot will create second-life battery packs using AutoMat project outputs, assembling and testing them for safety, functionality, and real-world usability per international standards. Equipped with control software and a "battery passport" for digital tracking, the packs will integrate safety and remote monitoring systems. Economical assessments will support product viability.